There are numerous laser welding tools obtainable, so it’s crucial to choose ones that fit your requirements and value range. Apart from various metals like metal, chrome steel, titanium, aluminum, nickel, and their respective alloys, lasers can be used to weld or be a part of a diverse range of supplies. These embrace not solely metallic substances but additionally non-metallic ones, corresponding to joining glass to steel. The vast range of materials makes laser welding even more profitable.

Therefore, remote control can be utilized, which can be achieved by an electric motor, gearbox, and relevant distant control circuit. This distant control device just isn’t solely easy to operate but in addition has anti-electric shock and power-saving features, which can achieve the aim of safe work and power saving. Finally, ultrasonic welds are as sturdy and sturdy as standard welds of the identical supplies — which is simply one of many causes the method is being utilized in automobile manufacturing. To make cars lighter and more fuel environment friendly, auto makers are turning to aluminum as the main metal in automotive bodies. Ultrasonic welding can be used to bond the steel in less time and at lower temperatures than conventional welding. The ultrasonic welding method described are good for materials (metals, plastics) that are similar. Let’s tackle this question by looking at how New Balance has used ultrasonic welding to assemble athletic shoes.

gun to make wire feeding potential. Welding aluminum comes down to choosing the proper welding process. Many instruments and strategies are designed for welding steel, however aluminum requires its personal approach and tools. The second selection is flux, which creates its own shielding gas and slag when uncovered to the high arc welding temperature. The flux’s inert gas and slag “encapsulate” the weld and maintain the gases in the air away. There is no shielding fuel required, and that is considered to be one of many easier welding strategies.

Read more about welding supplies near me here.

Is Laser Welding Business Right For Me?

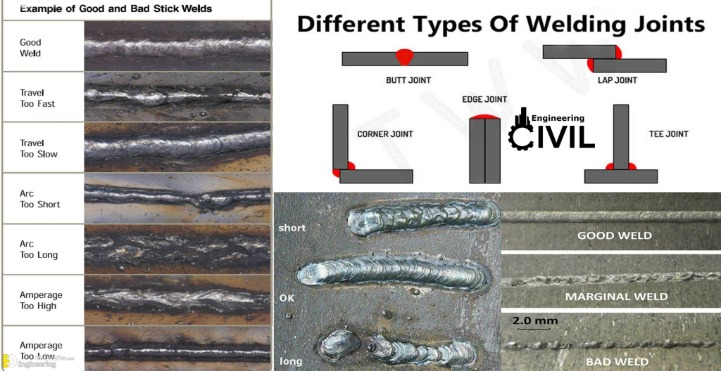

It can happen after the weld has solidified and may be attributable to a mix of welding stress, a brittle hard structure, the presence of hydrogen, and temperatures under 150°C. Porosity may be attributable to the contamination of the steel at hand, including by paint, oil, moisture, mill scale, and so on. As the warmth from the welding increases, these contaminants will remodel into gasses that then turn into trapped inside the weld pool, basically weakening the weld itself. In current years, nonetheless, a new method known as ‘friction stir welding’ (FSW) has been launched. This process makes use of mechanical friction by making use of stress and rotating the metals at excessive pace, which in turn causes them to fuse and kind a strong bond. Arc welding or “stick welding” as it’s referred, makes use of a flux covered rod to weld with.

How Does Arc Welding Work?

Read more about lancing here.

Basic Circuit Diagram of Arc Welding

You additionally can not make tack welds with thicker materials effectively. Lastly, to make use of this welding technique efficiently, all of the workpiece surfaces must be free from dirt and rust. However, as the present focus is on electrode composition, the connection between electrodes and the controls generally discovered on many in style inverter-based energy sources should be noted. Some of these controls include electrode selection, adjustable hot start, and adjustable arc drive. TIG welding is known as one of the hardest types of welding because it requires extra coordination and apply than other types of welding. The course of includes a foot pedal controlling the arc size, one hand supplying the sacrificial rod, and the welder’s different hand aiming the electrode at the work surface.