In the realm of industrial machining, precision and efficiency are non-negotiable. The key services fueling this precision include line boring, on-site machining, and bore repair. These specialized techniques ensure machinery operates flawlessly, maintaining productivity and safety standards.

Comprehensive Overview of Key Machining Services

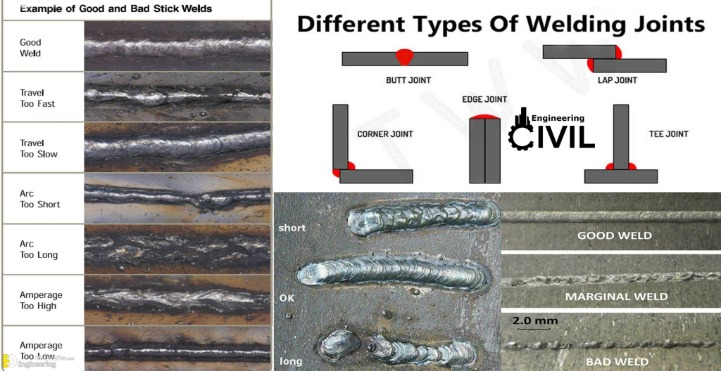

Read more about bore welding here.

Line Boring

Line boring involves enlarging a hole that has been drilled or cast in heavy machinery to ensure alignment and proper fitting. This service is crucial in maintaining the synchronization of multiple bores, preventing wear and tear, and extending the equipment’s lifespan.

- Enlargement and re-alignment

- Enhances machinery accuracy

- Reduces downtime

On-Site Machining

On-site machining offers the flexibility to perform repairs and adjustments directly at the machinery’s location. This minimizes transportation risks and ensures timely repairs, effectively reducing operational delays.

- Minimizes transportation risks

- Reduces operational delays

- Ensures immediate adjustments

Bore Repair

Bore repair is essential for restoring the functionality of worn or damaged bores. This process includes techniques such as bore welding and re-machining to bring the bore back to specification.

- Restores worn or damaged bores

- Includes bore welding and re-machining

- Ensures dimensional accuracy

Critical Techniques in Machining

Bore Welding

Bore welding involves adding material to the inside of a bore to repair damage or wear, followed by precise machining to restore its original dimensions. This technique is highly effective in extending the life of heavy-duty machinery components.

Slew Milling and XY Milling

Slew milling and XY milling are advanced techniques used to achieve precise surface finishes and dimensional accuracies on large, complex components. These methods are essential in industries requiring high-precision componentry.

- Ensures precise surface finishes

- Essential for high-precision industries

- Accommodates large, complex components

Bush Install

Bush installation is a process involving the insertion of a bushing to restore or enhance the functionality of machinery. It ensures improved load distribution and reduces wear on bearing surfaces.

Face Welding

Face welding is the application of a hard-facing material to a worn surface. This technique is crucial in restoring the wear resistance of machinery components, thus prolonging their service life.

Frequently Asked Questions

What is the importance of line boring?

Line boring ensures the alignment and synchronization of multiple bores, which is crucial for machinery accuracy and longevity.

Why choose on-site machining?

On-site machining minimizes transportation risks, reduces downtime, and allows for immediate adjustments, enhancing operational efficiency.

How does bore welding extend component life?

Bore welding restores the dimensions of worn bores by adding material and then machining it to exact specifications, thus extending the component’s usable life.

What are the benefits of slew milling and XY milling?

These milling techniques provide precise surface finishes and dimensional accuracies, essential for large, complex components in high-precision industries.

How does bush installation improve machinery performance?

Bush installation improves load distribution and reduces wear on bearing surfaces, ensuring smoother and more reliable machinery operation.

Harnessing advanced machining techniques like line boring, on-site machining, bore repair, and others mentioned can significantly enhance the performance and longevity of industrial machinery, ensuring that operations run smoothly and efficiently.